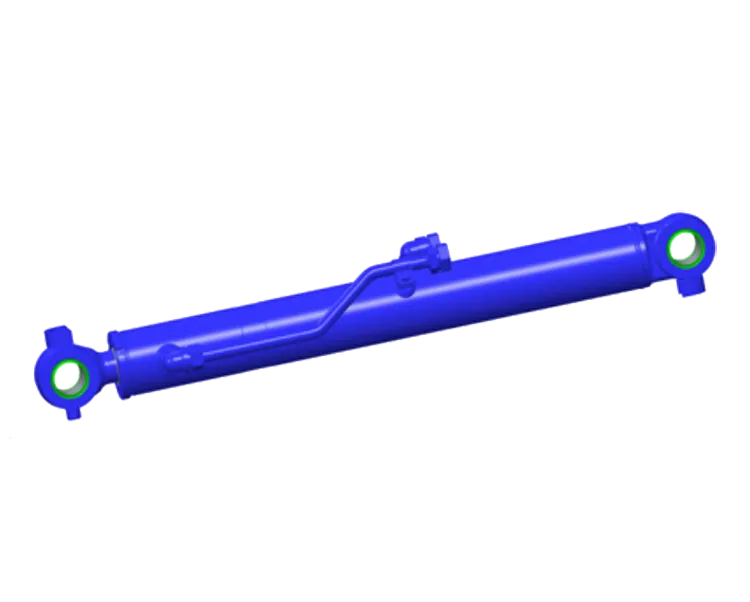

The hydraulic cylinder of a crane is essentially a linear actuator. In a crane, it drives various mechanisms of the crane to complete predetermined actions through the linear reciprocating motion of internal pistons. Its core function is to provide enormous pushing and pulling force, and achieve precise and smooth position control and speed adjustment.

The working performance of a crane, such as lifting capacity, lifting height, amplitude, and telescopic arm length, directly depends on the design and capacity of the hydraulic cylinder. A typical hydraulic crane (such as a truck crane) is usually equipped with multiple hydraulic cylinders, which are used for:

Main lifting/slewing cylinder: provides the main lifting force and the force for changing the angle of the boom.

telescopic cylinder: nested inside the boom, used to control the extension and retraction of the boom segments, changing the working radius and height.

Leg cylinder: extends before operation, supports the entire crane body, provides a stable working platform, and is crucial for safety.

Steering cylinder and other auxiliary cylinders: used to control auxiliary functions such as tire steering.

It can be said that without high-performance hydraulic cylinders, there can be no modern, efficient, and safe lifting operations.

| Product Name | Crane hydraulic cylinder |

| Rod Size | 18 mm - 2000 mm(0.71inch - 78.74 inch) |

| bore Size | 40-200mm(1.57 inch - 7.87inch) |

| Stroke | 10-15000mm(0.39 inch - 590.55inch) |

| Tipping Weight | 1 Ton - 100 Ton |

| Working Pressure | 2500psi - 8000psi(3000psi , 5000psi available) |

| Material | Carbon Steel/Cast Iron /Aluminum/Hard chrome plated Alloy Steel |

| Barrel/Tube | 1. Material: SAE1020(20#) , SAE1045(45#) ,16Mn(Q345B),27SiMn,etc. |

| 2. Technology: cold drawn ,hot rolled,forged | |

| 3. Surface Roughness: R0.16-0.32 | |

| 4. Choose by different working condition and requirements. | |

| Piston rod | 1. Material: SAE1045(45#),35CrMo,42CrMo4,etc. |

| 2. Technology: Quenched and tempered | |

| 3. Surface treatment: chrome plated, nickel-chromium plated, nitriding, nitrocarburizing | |

| Seal kits | 1. Hallite, NOK, SKF, Parker, Hercules,Trelleborg,China made,Taiwan made |

| 2. Choose by different working condition and requirements. | |

| Hydraulic Cylinder Types | Single Acting Hydraulic Cylinder,Double Acting Hydraulic Cylinder,Telescopic Hydraulic Cylinder, Welded Hydraulic Cylinder,Tie-Rod Hydraulic Cylinder,Bolted Hydraulic Cylinder, Re-phasing Systems Hydraulic Cylinder,Double Rod End Hydraulic Cylinder |

| Mounting Style | Earrings, flange, foot mounting, trunnion, cross tube, etc |

| Test | Static balance test |

| Surface treatment | Painting/sand blasting/oiled,Follow customers' requirement. |

| Application | Excavator boom arm bucket,Construction,Machinery,Agricultural Machine,Lift gate & Snow plow,Trash Compactors,etc |

The working principle of hydraulic cylinders is based on Pascal's principle. In a closed container, the pressure applied to a stationary fluid will be transmitted simultaneously to all points of the fluid and the walls of the container at an equal value.

1. Working principle:

The hydraulic pump on the crane converts the mechanical energy of the prime mover (diesel engine or motor) into the pressure energy of hydraulic oil. High pressure oil is precisely distributed through control valves (such as directional valves and balance valves) and sent into a certain chamber (rodless chamber or rodless chamber) of the hydraulic cylinder. High pressure oil acts on the effective area of the piston, generating a huge thrust or tension that drives the piston rod to move in a straight line. The oil in the other chamber is pressurized back into the tank. By controlling the flow rate, pressure, and direction of the hydraulic cylinder oil, the movement speed, output force, and direction of the piston rod can be precisely controlled.

2. Basic structure:

A standard hydraulic cylinder is mainly composed of the following components:

Cylinder: The main body of a hydraulic cylinder is a high-precision, high-strength cylindrical structural component. The inner wall is usually subjected to precision boring, rolling or honing treatment, with extremely high surface smoothness and geometric accuracy, to reduce the wear and internal leakage of seals. The material is mostly high-strength alloy steel.

Piston: Located inside the cylinder, it divides the cylinder into two sealed chambers (with rod chamber and rodless chamber). The piston is equipped with a sealing ring to prevent oil leakage between the two chambers. It directly converts the pressure of the oil into mechanical thrust.

Piston rod: It is usually a high-strength solid or hollow rod, with one end connected to the piston and the other end extending outside the cylinder and connected to the load (such as the boom). It is a key component for transmitting force, and its surface is usually treated with hard chrome plating, which has extremely high hardness, wear resistance, and corrosion resistance.

Guide sleeve: Installed at the front end of the cylinder, it guides and supports the piston rod, preventing it from bending and wearing due to lateral force. Internally, there are usually guide rings and rod sealing rings.

Sealing device: the soul of hydraulic cylinders. Including piston seal (to prevent internal leakage), piston rod seal (to prevent external leakage), dust ring (to prevent dust and impurities from entering the cylinder), guide ring/support ring (to support the piston and piston rod and prevent metal contact), etc. The sealing performance directly determines the efficiency and lifespan of the hydraulic cylinder.

Cylinder head and cylinder bottom: Seal both ends of the cylinder barrel separately, forming a sealed chamber together with the cylinder barrel.

Buffer device (optional): For high-speed hydraulic cylinders, a buffer structure is installed at the end of the stroke to prevent severe collisions between the piston and the cylinder head/bottom, reduce impact, lower noise, and protect the cylinder body.

Exhaust device: Usually, an exhaust plug or valve is installed at the highest point of the cylinder to eliminate air mixed into the hydraulic oil and prevent the actuator from crawling.

According to the requirements of different working conditions of cranes, hydraulic cylinders are mainly classified into the following ways:

Divided by mode of action:

Single acting hydraulic cylinder: With only one oil port, the pressure oil can only push the piston to move in one direction, and the return relies on external forces (such as spring force or the weight of the load). It is commonly used in low demand situations or clamping devices in cranes.

Double acting hydraulic cylinder: It has two oil ports, and pressure oil can alternately enter the two chambers to achieve bidirectional movement of the piston. This is the most mainstream and common type of crane, and most of the main action cylinders are double acting cylinders.

Divided by structural form:

Piston type hydraulic cylinder: the most common form, as described above.

Piston type hydraulic cylinder: The piston rod is relatively thick, usually single acting, and relies on its own weight or other mechanisms to return. Commonly used for large hydraulic presses or long stroke crane leg cylinders.

Telescopic hydraulic cylinder: composed of multiple cylinder tubes stacked together, with a large stroke and a short length after retraction. This is the core component of the telescopic arm of a car crane, which can effectively increase the working height and radius without affecting the overall size of the machine during transportation. Its structure is complex and requires extremely high synchronization and sealing.

Swing hydraulic cylinder (hydraulic motor): The output is rotational motion, commonly used in the slewing mechanism of cranes.

RELATED

RELATED

Copyright © 2025 Wuxi Hengxin Zhicheng International Trade Co., LTD All rights reserved Applications

This website uses cookies to ensure you get the best experience on our website.